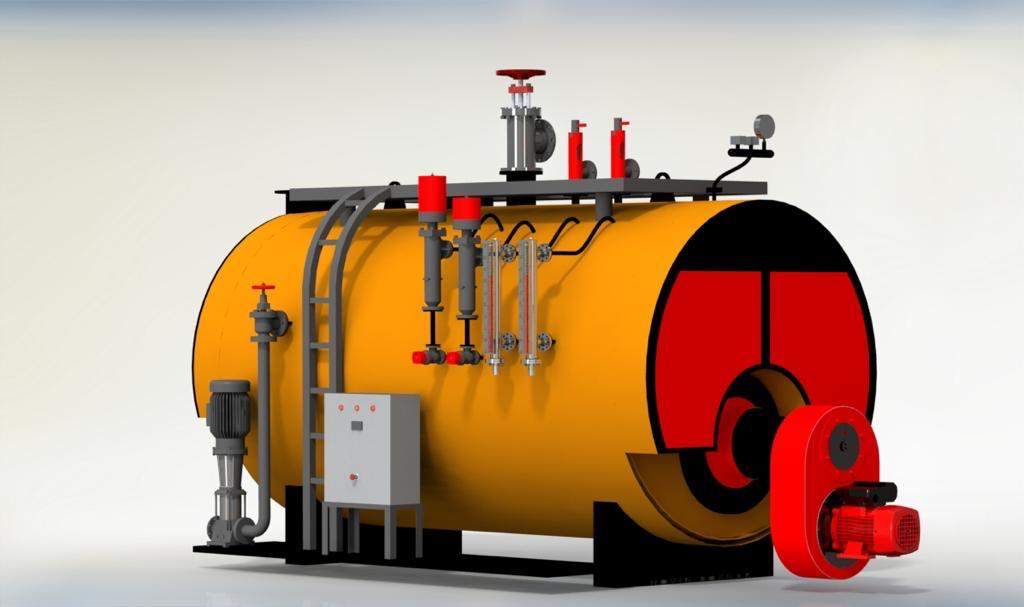

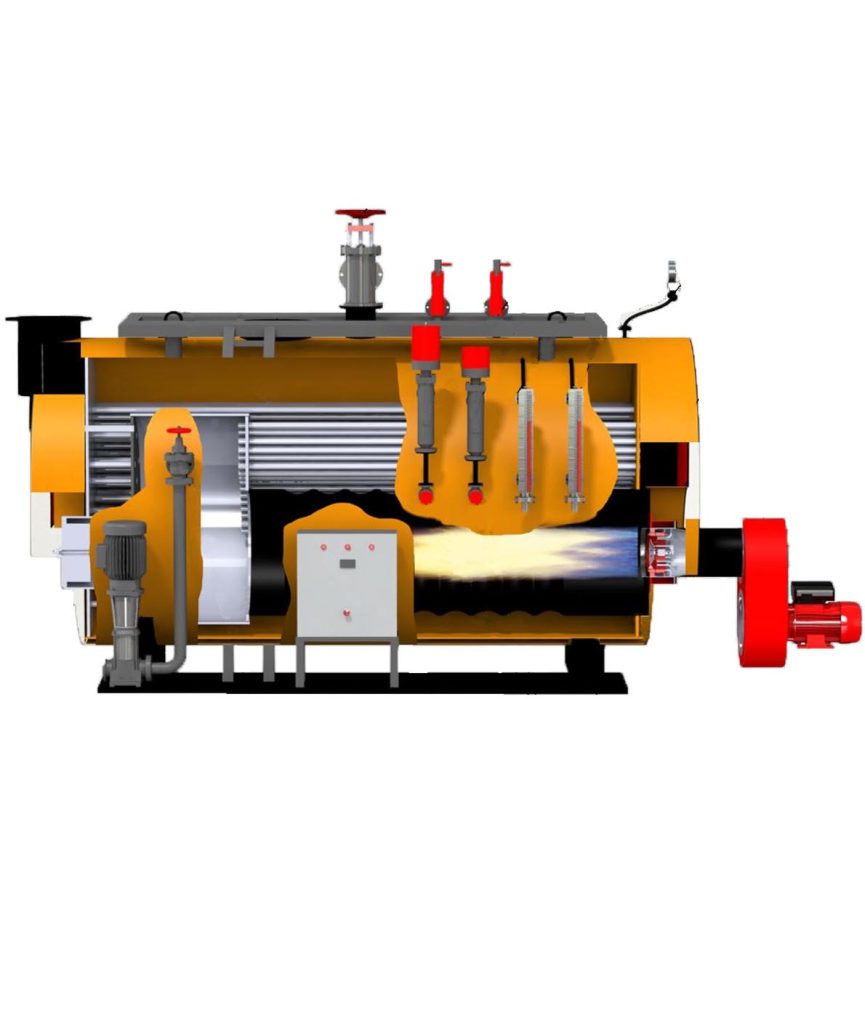

In steam boilers and hot oil boilers, pipes and tubes play a vital role in heat transfer.

In steam boilers, tubes (fire tubes) pass hot gases from combustion through them, and their heat is transferred to the water surrounding the tubes, producing steam. In hot oil boilers, thermal oil passes through the coil tubes, and the heat from combustion is transferred to the oil, heating it.

Pipes (tubes) in the boiler:

Fire Tube:

These tubes are used in fire tube boilers and hot gases pass through them.

Application:

Transfer of heat from hot gases to water surrounding the tubes to produce steam.

Pressure:

Fire tube boilers are typically used to produce steam at relatively lower pressures and temperatures.

Tubes in a hot oil boiler:

Coil:

In hot oil boilers, thermal oil passes through spiral coils.

Application:

Heat transfer from hot gases to thermal oil and increase its temperature.

Pressure:

Hot oil boilers can heat oil to high temperatures (e.g. 300°C) without the need for high pressure.

The main difference in application:

Boiler:

Steam generation using heat transfer from hot gases to water.

Hot oil boiler:

Generating the heat required to heat thermal oil for use in industrial applications.

Table of differences between (Tube) and (Pipe)

| Characteristic | (Pipe) Pipe | (Tube) Tube |

| Basic definition | Vacuum tubes for transporting fluids (gas, liquids, powdered solids) under pressure | Hollow tubes with various applications (structural, heat transfer, mechanical) and high dimensional accuracy |

| Common standards | (Carbon Steel) B36.10 ASME (Stainless Steel) B36.19 ASME (Oil & Gas) 5L API | (Seamless Tube) ASTM A269 (Boiler Tube) ASTM A213 (Mechanical Tube) ASTM A511 |

| Diameter measurement method | Nominal Pipe Size (NPS) Example: NPS 2 inches 2 # Exact outside diameter ≠ inches. | Actual Outer Diameter (OD) Example: 25.4 tube: Exactly 1mm in outer diameter |

| Wall thicknessﺿﺧﺎﻣت دیواره | It is defined by the thickness table (Schedule) (e.g. Sch 40, Sch 80). The thickness increases with increasing Schedule number. | Thickness is specified precisely in millimeters or inches (example: 1.5mm). |

| Dimensional accuracy | Dimensional tolerance pointer. Strength/Focus on endurance, not precision. | High dimensional accuracy in outer diameter, thickness and surface finish. |

| Main applications | (Water, Oil, Gas) Fluid Transfers | Fluid Transmission Lines (Water, Oil, Gas) Industrial and Construction Piping Systems Pressure Tanks |

| Contact method | ⦁ Threaded Connections ⦁ Flanged | ⦁ Compression Fittings ⦁ Brazed Connections |

| Characteristic | (Pipe) Pipe | (Tube)Tube |

| Welding type | ⦁ Welding (Butt/Groove Weld) | ⦁ Orbital Welding |

| Raw materials | ⦁ Carbon steel, stainless steel, PVC, CPVC, HDPE | ⦁ Stainless steel, copper, brass, aluminum, titanium, special alloys |

| Flexibility | The original tube is usually designed for fixed installation. | Flexible tube types have higher flexibility. |

| Pressure Tolerance Calculation | Allowable pressure based on ASME B31 standards (e.g. B31.3 for process). | Based on (for example, Bourse’s formula) the diameter of the calculated volume is allowed by more precise formulas. |

| Product Sample | Pipeline construction, oil transmission lines, water pipes | Heat exchanger pipes, hydraulic system pipes, motorcycle frame |

Additional key points:

1. Nominal Pipe Size (NPS):

The actual outside diameter changes with increasing NPS (e.g. NPS 2 06.3 ≈ mm, NPS 14 553.6 ≈ mm).

2. Tube wall thickness:

It is also commonly expressed as (Birmingham Wire Gauge) BWG or (Standard Wire Gauge) SWG.

3. Surface quality:

Tubes often have a high surface finish (such as mirror polishing) to be suitable for sensitive applications (medical, semiconductor).

4. Price:

Tube is usually more expensive than pipe due to higher manufacturing precision and material properties (e.g. 613L stainless steel).