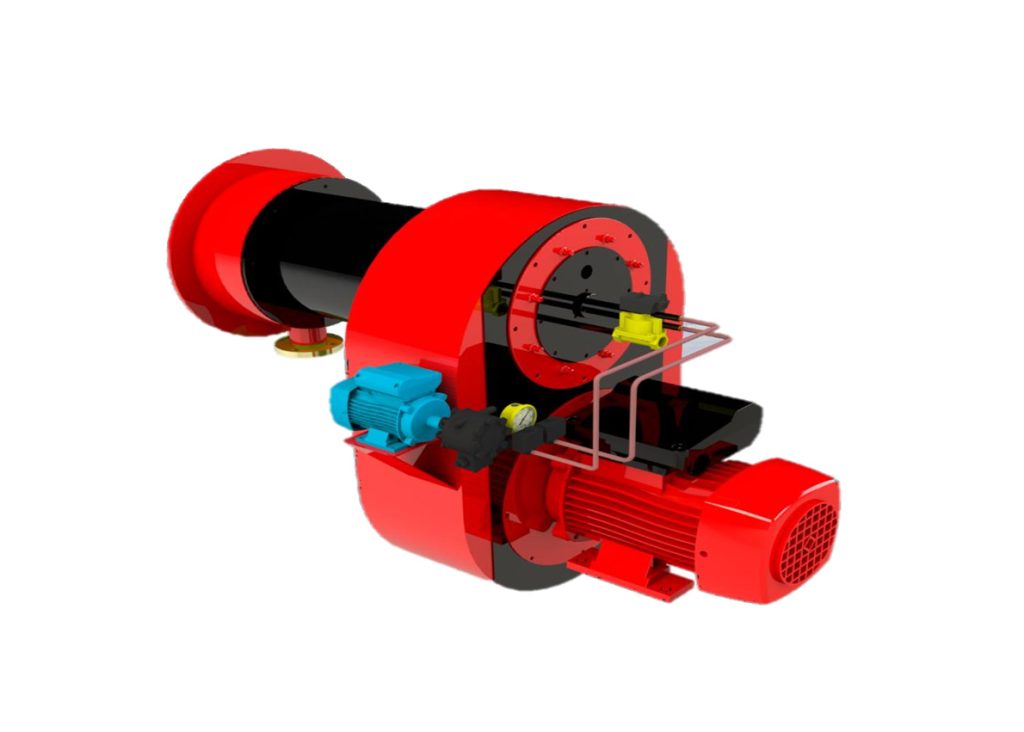

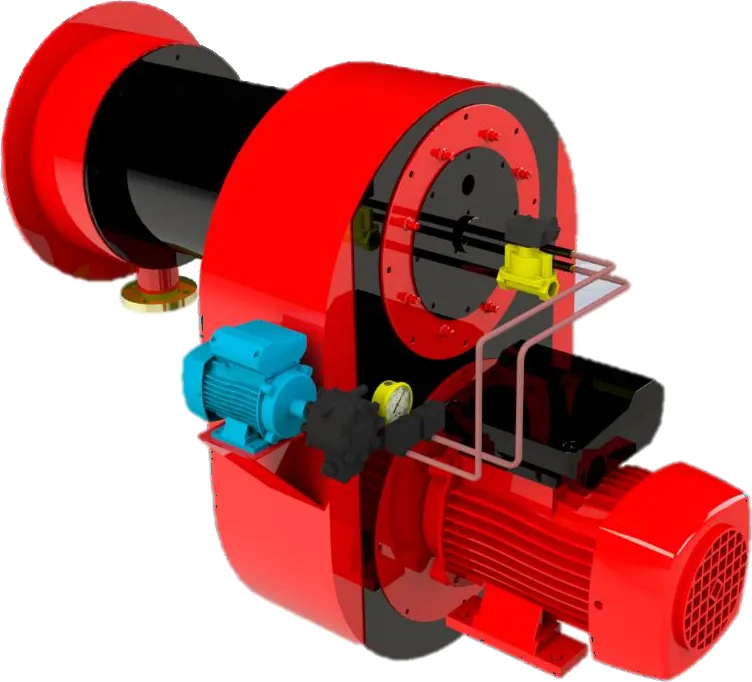

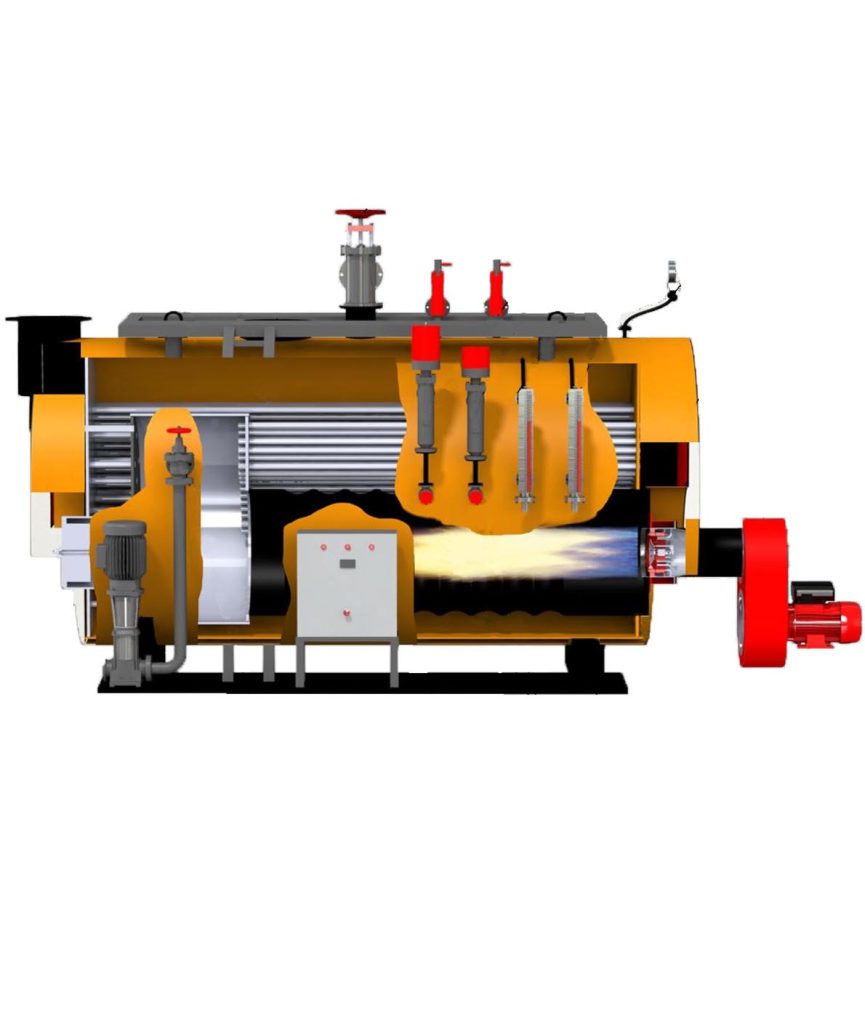

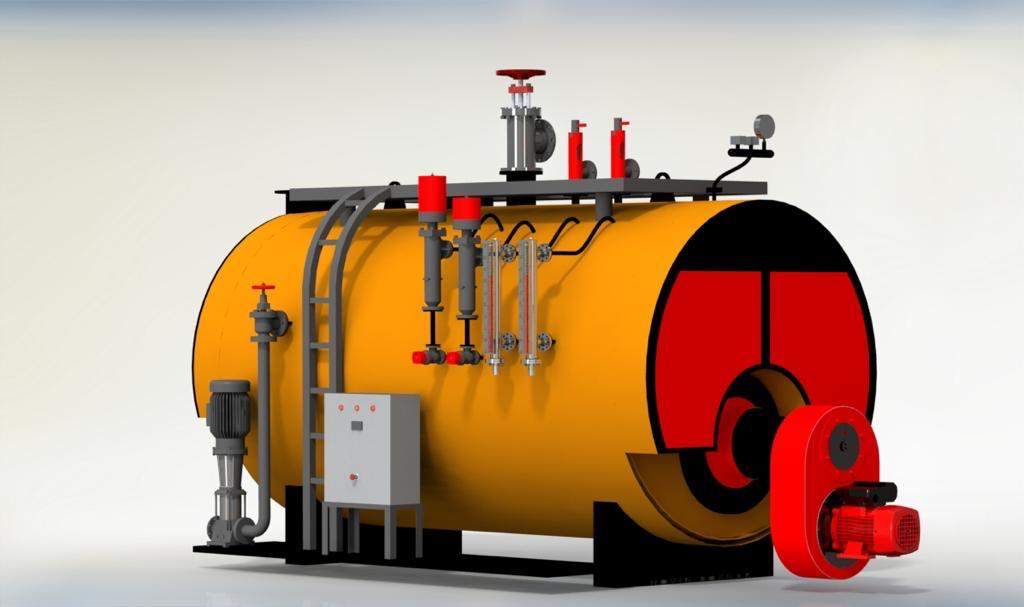

Boiler components

| 1 – Torch | 11 – Rapper |

| 2 – Front smoke box | 12 – Chimney |

| 3 – Barometer | 13 – Accordion oven |

| 4 – Pressure switch | 14 – Chassis |

| 5 – Magnetic fountain | 15- The lion under the moustache |

| 6 – Magnetic control level | 16 – Electrical panel |

| 7 – Safety valve | 17 – Water supply valve |

| 8 – Steam outlet valve | 18 – Water feed pump |

| 9 – Manhole cover | 19 – Flame inspection hatch |

| 10- Fire-eating pipe | 20 – Rear smoke box |

Boiler construction

Boiler manufacturing is a complex process that involves various steps including design, cutting, bending and welding of sheet metal, as well as final testing and inspection. Boilers are divided into two categories based on design: watertube and firetube, each with its own manufacturing steps.

General steps for building a steam boiler:

1. Design and Drawing: At this stage, computer drawings of the boiler are prepared according to the project needs and technical specifications.

2. Material Supply: Metal sheets (usually steel) are supplied with the thickness and dimensions required for the construction of the boiler.

3. Cutting: Metal sheets are cut to the required sizes using cutting machines.

4. Bending:

The cut sheets are bent into cylindrical or other required shapes. This is usually done using rolling machines.

5. Assembly and welding: The bent parts are welded together to form the main body of the boiler.

6. Manufacturing of ancillary components: Components such as furnaces, return chambers, and tube sheets are also manufactured.

7. Final assembly: All parts are connected together and the boiler takes its final form.

8. Testing and Inspection: The boiler is tested for weld quality, pressure and other safety parameters.

9. Painting and insulation: The boiler is painted and insulated to prevent heat loss.

10. Equipment Installation:

Auxiliary equipment such as pumps, valves, and instrumentation are installed on the boiler.

Types of steam boilers

Firetube boiler:

In this type of boiler, hot gases pass through the tubes and water is located around the tubes.

Water Tube Boiler:

In this type of boiler, water passes through the tubes and hot gases surround the tubes.

Important points:

The choice of boiler type (watertube or firetube) depends on various factors such as capacity, working pressure, and fuel type.

Specific standards are followed in the construction of a steam boiler to ensure its safety and efficiency.

Welding is of great importance in boiler construction and must be performed by skilled personnel using appropriate equipment.

It is essential to follow safety precautions during the construction and operation of a steam boiler.